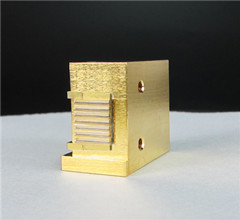

Product outline

Macro channel laser diode stacks are good for both quality and price. The structure of packaging is flexible and it has no special need for water. We deliberate on diode laser packaging and the design of laser stack. Finally we find the method to overcome macro channel laser diode stacks’s chip burning and we developed the high reliability laser diode stacks for hair removal.

Technical parameters

|

Output Power |

300W |

500W |

1000W |

|

Wavelength |

808nm(800-810nm) |

|

Number of bars |

1-20Pcs |

|

Solder type |

Hard solder or soft solder |

|

Typical Pulse Width |

10ms~200ms |

|

Repetition Rate |

0~10Hz |

|

Max Duty Circle |

20% |

|

Operation Current |

40A |

40A |

40A |

|

Operation Voltage |

<12V |

<20V |

<40V

|

|

Cooling Requirement |

1. Flow Rate: >4.5L/min

2. Water quality: Industrial grade, anti-freeze ossible, particle filter<100µm

3. Chiller water Temperature: 15°C-25°C. |

Working principle

The process of diode laser’s working is the change from electric energy to light and heat energy.When the chip which is inside the macro channel is working, the cooling water flow inside the laser stack and bring the extra heat and make sure the chip going well.

Technology advantage:

1. JGI focuses on diode laser packaging technology and especially in aesthetic applications. We research and design the professional technology for macro channel hard solder packaging and overcome the shortage which is easily to burn.

2. A long life and super power.

3. Unique precision plating technology and shape

4. The power and wavelength of diode laser is customizable which can satisfy customer’s needs.

5. The size of diode laser is customizable which is assorted to installing structure.

6. Repair other brands of macro or micro channel diode laser.